High Pressure Laminate (HPL)

Also Known As: Plastic Laminate, 'Formica'

HPL OFFERS MORE DESIGN VARIETY THAN OTHER LAMINATES, AND IS EASY TO FABRICATE IN THE FIELD. material: HPL. Photo by Kenn busch photography. all rights reserved.

What is HPL?

One of the most familiar and widely used engineered decorative furniture surfaces, HPL was originally made famous by the Formica Corporation. It is sold in rigid sheets that are about .028 to .048 inches thick, and must be glued to a substrate, usually particleboard, for furniture and interior applications.

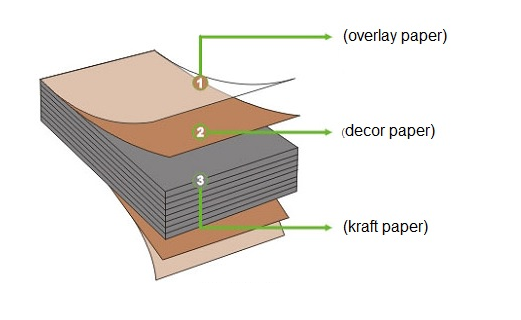

HPL is 60-70 percent paper, saturated with different kinds of plastic resins.

GRAPHIC COURTESY OF WILSONART

The core of a sheet of HPL is made of several layers of kraft paper (similar to shopping bag paper) saturated with phenolic resin. The visual layer is a sheet melamine-impregnated décor paper with a solid color or printed design, which is topped with a protective wear layer that can also carry metallic or other inclusions for extra design flair.

The material also is available in many different textures.

Why HPL?

HPL is easy to work with and very durable. It’s also available in a vast variety of designs, including custom silkscreened and digital prints.

It differs from materials like TFL, 3DL and decorative foils in that HPL components can be fabricated in the field. It can be cut with standard woodworking tools, and commonly available adhesives are used to bond it to the substrate. Fabricators commonly will cut HPL into strips for matching panel edges.

HPL offers higher impact resistance than other laminates, and has proven itself over 75 years of use in commercial and residential applications.

Special postforming grades of HPL allow fabricators to bend the material to create rounded or contoured edges on opposite, straight sides of a rectangular panel, creating the familiar profiled edges on shelves, countertops, and back splashes. The edges without profiles typically have flat, 90-degree edges.

Because HPL is so easily fabricated, designers and fabricators can choose from many different substrate options to maximize value and performance.

Where is HPL used?

Commercial and residential cabinet casework, doors and drawer fronts – offices, hotels, healthcare

Worktops, tabletops, kitchen counters

Retail displays, transaction counters, shelves, walls

Architectural wall panels, elevator cab wall panels

Signage and branded surfaces (with digitally printed and silk-screened designs)

Laminate flooring

In combination with TFL, lightweight papers, and 3DL with matching or complementary designs

Applications where you want a design that’s not available in any other material.

Commercial: HPL is found extensively in fast-food restaurants, on transaction counters, booths, tabletops, walls, and bathroom dividers. You’ll also see it in offices on reception desks and work surfaces, on hotel room vanities, in elevator cabs, and on airline check-in desks. Care must be taken when using HPL in healthcare and education settings: the edge seams may harbor bacteria, and sharp edges and corners can cause injuries.

Residential: Countertops and vanities, mudrooms, desktops, and on any surface that will be subject to high use or heavy cleaning.

HPL Properties and Performance

HPL sheets faces are glued to a substrate, usually composite wood: particleboard, MDF, or – rarely – plywood

Scratch, wear, impact, and heat resistance sets the standard for laminates

Enhanced wear- and chemical-resistant surfaces are available

Edge treatments are required to protect the surface integrity of HPL-surfaced panels

Panel faces are water and moisture resistant, unlike veneers

Special cores may be specified for moisture and fire resistance

HPL is often used as a more durable, economical alternative to veneer and stone surfaces in high-use applications.

HPL Design

Surface Visuals: Décor papers used in HPL are essentially the same as for TFL. They’re printed on décor papers either on rotogravure or digital inkjet presses with water-based inks. The printing system must be compatible with downstream process – saturating the papers with resins, and pressing them to the composite wood core.

Textures: Woodgrains, gloss/matte variations and other texture effects are imparted to the surface during pressing, using either engraved steel plates or textured release papers. Some of these textures may be “synchronized,” meaning the “ticks” in a woodgrain texture, for example, align perfectly with woodgrain details in the décor paper. HPL can carry deep stone and wood textures, as well as the feel of unfinished, raw wood.

Shapes/Form: HPL-surfaced panels have flat faces and can easily be cut into unique shapes.

Edges: Because HPL is easy to fabricate in the field, unique panel shapes can be edged with narrow strips of HPL cut from the same sheet used for the panel face. Standard HPLs can be glued to gently curved edges. Any sharp angles in an edge require the HPL to be cut.

Special postforming grades of the material may be bent around radiused or contoured edges of the substrate to form bullnose, no-drip, or other edge styles.

Matching or complementary edgebanding in other materials is available in various thicknesses.

Matching Materials: HPL producers publish guides to design matches in complementary materials – TFL, 3DL, decorative paper foils, and edge treatments. HPL is commonly combined with TFL and 3DL to increase design flexibility and to value-engineer the performance required for each surface.

Material Makeup and Manufacturing

The kraft, décor, and wear layers are collated into a sandwich and placed in a large daylight press.

Textured steel plates or release papers are placed over the décor side of the sandwiches.

The layers of core, décor, and wear papers are fused into a sheet under heat and pressure.

This process also embosses the texture into the top of the HPL sheet.

Many different HPL sandwiches can be pressed in a single pressing cycle, each with different decors and textures, making it efficient to produce several different designs at once.

HPL sheets are then cooled, stacked, and shipped to OEMs, fabricators and distributors, and retailers.

HPL Component Fabrication

Fabricating HPL components is a fairly low-tech affair. Surfaces and edges can be glued to the faces and edges with contact adhesives at room temperature, allowing contractors and installers to fabricate many HPL components on-site.

As the HPL adhesive cures, it can cause the substrate to warp. Gluing a lower-grade non-decorative HPL onto the back (or bottom) of the panel will keep the panel balanced. If the panel will be visible on both sides, like a bathroom partition, the same decorative HPL can be applied to both faces.

Environmental Impact

HLP panels are based on composite wood cores that use recycled wood fiber that would otherwise be landfilled or incinerated, Composite wood panels made in North America have composite wood cores that have been found to be “better than carbon neutral,” sequestering more carbon than is expended in the panel’s manufacture from cradle to gate.

The material’s realistic woodgrain visuals and textures allow designers to replace fragile and rare woods and veneers with more durable, design-consistent, and cost-effective HPL-surfaced panels.

Because of its high cellulose content, HPL may be safely incinerated for energy.

HPL offers these LEED credit opportunities:

MR 7: Certified Materials – North American composite wood panels are FSC certified

MR 4.2: Recycled content – North American composite wood panels contain

EQ 4.4: Low-Emitting Materials – North composite wood panels meet CARB II requirements

HPL Suppliers

Abet Laminati

Arborite

Arpa USA

Elesgo by DTS

Formica Group

Interior Arts / Chemetal

iZone Imaging

Lamin-Art, Inc.

Lamitech S.A.

LIRI America Corp.

Octopus Products Ltd.

Panel Processing

Panolam Industries Int'l.

Pentco Group/Greenlam

Polyrey

Resopal GmbH

Uniboard

Wilsonart Int'l