What are Hardwoods?

Hardwoods come from angiosperm trees, which are plants that produce seeds with some sort of covering. This is opposed to softwoods, which come from gymnosperm trees, typically having needles and cones. The terminology “hardwood” and “softwood” is somewhat misleading, as it does not necessarily denote the actual hardness or softness of the wood.

Key characteristics of hardwoods:

- Source: They come from deciduous trees, which are trees that lose their leaves annually. Examples include oak, alder, maple, cherry, birch, and walnut.

- Density and Hardness: Generally, hardwoods tend to be more dense and harder than softwoods, though there are exceptions. This makes them ideal for uses where strength and durability are required.

- Grain and Texture: Hardwoods often have a more varied and attractive grain than softwoods, making them popular for furniture, flooring, and cabinetry.

- Slow Growth Rate: Hardwood trees usually grow more slowly than softwood trees, which can make hardwoods more expensive due to the longer time it takes for the trees to reach maturity.

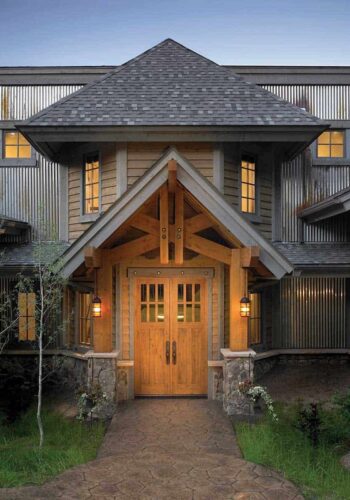

- Uses: Due to their properties, hardwoods are commonly used for high-quality furniture, flooring, construction, cabinetry, and other applications where durability and aesthetics are important.

Despite the name, not all hardwoods are harder than softwoods. For example, balsa wood is one of the softest woods available, but it’s classified as a hardwood. The distinction is based on the botanical classification of the trees and not on the physical hardness of the wood.

Why Hardwoods?

Workability

Hardwoods are beautiful, durable, can be enhanced with a wide range of stains, finishes and other treatments, and are easily worked with basic tools as a hobbyist, as well as with the latest energy-efficient manufacturing commercial production lines.

History

There was a time when wood was one of only a few building materials widely available, along with stone, brick, mud and clay. You can find buildings made with wood dating back to the year 600 that are still in daily use, and furniture made with wood dating back to ancient Egypt. Those iconic columns from Greek and Roman architecture were inspired by carved wooden columns.

Longevity

Furniture, flooring, and millwork crafted from hardwoods have demonstrated enduring resilience and timeless appeal across various cultures through the centuries. They age gracefully with minimum care and become more valued with age.

Climate-Positive Carbon Sequestration

Hardwoods store naturally captured atmospheric carbon. In most cases, thanks to its ease of manufacturing, this stored carbon more than offsets the amount of carbon released in harvest, manufacturing, and use. This is why products made from hardwoods are considered climate-positive, or carbon-negative.

Infinitely Renewable Resource

Wood from managed forests are considered an infinitely renewable resource. In North America, for every tree harvested 2.3 new trees are already growing. Replanting is rarely necessary. Harvesting older and dying trees opens up the forest canopy, providing the next generation with the sunlight and space it needs grow to full maturity.

- Since 1952 hardwood growing stock (trees greater than 5″ in diameter) has increased by 82%

- Hardwood sawtimber (large trees) has doubled since 1952

- 70% of precolonial forest lands are still flourishing today

- Hardwood fiber is growing about twice as fast as we are using it

Biophilia

The concept of biophilia came from Edward O. Wilson, who hypothesized that humans have an innate tendency to seek connections with nature. Biophilic interior design brings natural elements and patterns indoors. The natural visuals, tactile warmth, acoustic, and other properties of hardwoods are proven to be beneficial for mental and physical health.

Supporting Rural Economies

The hardwood lumber industry supports living-wage jobs and small businesses in rural communities throughout North America, where there may otherwise be few options.

Where Are Hardwoods Used?

In short, everywhere.

Hardwoods are found in furniture, cabinetry, millwork and paneling, floors and ceilings, in residential and commercial projects, as well as smaller things like baseball bats, tool handles, skateboards, utensils, and decorative items. Its workability is unique amongst building materials in that you don’t need sophisticated equipment or capital-intensive factories to convert it into furniture or objects; simple tools in a garage will do. You probably know at least one such hobbyist!

In engineering and construction, hardwood’s strength-to-weight ratio is a critical factor. Hardwoods are sometimes preferred in applications where the extra weight is not a downside, and the added strength and durability are important. For example, hardwoods might be used for joists, beams, or flooring in certain architectural contexts.

Lower grade hardwoods are also commonly used for durable consumables like pallets and railroad ties, made from lower quality trees in managed hardwood forests, or from the parts of hardwood trees not suitable for furniture or millwork.

Hardwoods Properties and Performance

Hardwood’s properties vary from species to species, and from one cut of lumber to another. They offer a variety of densities, and different grain and color characteristics, which can be accentuated and enhanced with solvent- and water-based stains and finishes.

As mentioned above, hardwoods generally have a high strength-to-weight ratio. This means they provide substantial strength and durability without being excessively heavy. For example, oak and maple are known for their high strength and moderate weight, making them popular choices for heavy-use applications like flooring and commercial furniture.

APPLICATIONS

- Cabinetry

- Doors

- Architectural millwork

- Wall and ceiling panels

- Flooring and stairs

- Commercial desks, conference tables, credenzas, reception desks, feature walls

- Fine residential furniture

- Countertops and work surfaces

- Outdoor decking and furniture

- Turned objects

- Windows

Species Gallery

Material Makeup and Manufacturing

In the purest sense, hardwoods manufacture themselves as trees grow. But their actual makeup is fascinating.

Hardwoods, like all wood, are composed of a complex combination of organic materials. These components give hardwood its strength, durability, and characteristic grain patterns. The primary components of hardwoods include:

- Cellulose: Cellulose is the most abundant organic polymer on Earth and a key structural component of wood. It forms the cell walls of wood fibers and provides strength and rigidity. Cellulose fibers are held together in a matrix, which helps give wood its overall strength and flexibility.

- Hemicellulose: This is a group of complex sugars that, along with cellulose, forms the cell walls of wood. Hemicellulose is not as strong as cellulose and is more susceptible to degradation by water, contributing to wood’s hygroscopic properties (tendency to absorb and release moisture).

- Lignin: Lignin acts as a natural binder or ‘glue’ in wood, holding the cellulose fibers together. It is responsible for much of the compressive strength of wood and also contributes to its resistance to decay. Lignin content is typically higher in hardwoods than in softwoods, which partly explains the increased density and hardness of hardwoods.

- Extractives: These are various organic compounds that are not part of the structural cellulose-hemicellulose-lignin complex. Extractives can include resins, tannins, oils, waxes, and colorants. They often contribute to the color, odor, and natural decay resistance of the wood. The composition and quantity of extractives can vary widely among different hardwood species.

- Water: Freshly cut wood contains a significant amount of water, either within the cell walls (bound water) or in the cell cavities and spaces between cells (free water). The drying process (seasoning) removes much of this water, reducing the wood’s weight and increasing its strength.

- Minerals and Other Trace Elements: These are present in small amounts and can include nutrients absorbed from the soil. While they make up a very small part of the wood’s composition, they can sometimes affect the wood’s properties, such as its burning characteristics or color.

Hardwoods are distinguished from softwoods not by the presence of these components, but by their structure and proportion. Hardwoods typically have a more complex structure, with vessels (porous cells) that transport water and nutrients, and a generally higher density due to the tighter packing of cells and higher lignin content. This structural difference results in the characteristic grain patterns, hardness, and other physical properties associated with hardwood.

Environmental Details

Hardwood lumber offers several environmental benefits, especially when it is sourced sustainably and managed responsibly. These benefits contribute to both ecological balance and the promotion of sustainable practices in the timber industry. Here are some of the key environmental advantages of hardwood lumber:

- Carbon Sequestration / Climate Positive Carbon Sequestration: Trees absorb carbon dioxide from the atmosphere during their growth process, storing carbon in their wood and releasing oxygen. This natural process of carbon sequestration helps mitigate climate change. When hardwood trees are harvested and processed into lumber, much of this carbon remains stored in the wood products for the duration of their life cycle.

- Sustainability and Renewability: Hardwood is a renewable resource. When hardwood forests are managed sustainably, new trees are planted or naturally regenerate to replace those that are harvested. This cycle ensures a continuous supply of wood while maintaining the health and balance of the forest ecosystem.

- Biodiversity Preservation: Well-managed hardwood forests support biodiversity. They provide habitat for a wide range of species, from birds and insects to mammals and other plants. The varied structure of these forests, including different tree species and ages, contributes to a rich and balanced ecosystem.

- Low Embodied Energy: Compared to many other building materials like steel or concrete, wood requires less energy to process, transport, and use. The embodied energy in hardwood lumber – the total energy required to produce it – is relatively low, which reduces its overall environmental impact.

- Biodegradability and Recycling: At the end of its life, hardwood lumber can be recycled or will biodegrade naturally, adding organic matter back to the soil. This contrasts with many synthetic materials that may take hundreds of years to decompose and can release harmful substances as they break down.

- Air and Water Quality: Forests play a crucial role in maintaining air and water quality. They filter air pollutants and stabilize soil, reducing erosion and protecting waterways. Sustainable forestry practices help maintain these vital ecosystem services.

- Eco-Friendly Alternatives to Less Sustainable Materials: In many applications, hardwood can be a more sustainable option than materials like plastics, metals, or composites, which have higher environmental costs in terms of resource extraction, manufacturing, and disposal. The relative carbon footprint figures are astounding!

- Local Economic and Environmental Benefits: Sourcing hardwoods from local, sustainably managed forests can reduce transportation emissions and support local economies. It also encourages the maintenance of forested land, which can be threatened by development or conversion to other less sustainable land uses.

To maximize these environmental benefits, it’s important for consumers and industries to support hardwood lumber that is sourced from forests managed under sustainable forestry practices. Certifications like the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI) can help consumers identify such sustainably sourced hardwood products.

Hardwoods Suppliers

There are hundreds of hardwood lumber suppliers of all sizes across North America, too many to list in detail here.

A great place to start is the membership of the National Hardwood Lumber Association.

We thank the following companies for their support of this Hardwood Lumber Material Guide.

- Menomonie Tribal Enterprises

- NWH