Much More than Meets the Eye

Capturing the soul of rare and fragile materials for a greener future

Buried deep in our collective soul is the drive to never forget who we are. We do this by trying to understand where we’ve been, preserving important milestones in our cultural heritage and sharing them so that future generations might be informed and inspired.

Preserving our cultural past is literally both an art and a science. There’s much more to a great painting than meets the eye, and capturing it so completely that people who’ve never even been on the same continent as the original can truly experience its beauty and energy requires carefully capturing every possible aspect: color, glossiness and texture.

If you think of a painting as a performance, color is the song; texture is the dance.

Scanning Rare Materials

For example, in the world of fine art reproductions, Metis makes it possible for Modern UV printers are able to build up textures and print color on top of them, faithfully reproducing every stroke of a paint-laden brush or palette knife scrape of Van Gogh’s dramatic impasto style.

Before such a performance can be reproduced, it must be captured. There are very few technologies able to “see” such a masterpiece in its entirety, and even fewer capable of delivering capture data that’s user- and work-flow friendly.

METIS, a company based in Rome that specializes in ultra-high-quality scanners, has cracked the code on preserving the some of the most important artistic works in western civilization. Granted, coming from Rome gives them a bit of a leg up.

“We’ve done a lot of work documenting items in the Vatican archives. These pieces present plenty of challenges when it comes to handling and scanning.”

— Rob Lawrence

“Very fragile materials often cannot be put under glass and smoothed of wrinkles, tears, creases and bows in the surface…and yet they want a one-to-one representation of the original for precise preservation. For instance, maps that are centuries old are still used in territory and land rights disputes, so accuracy is critical.

“Ancient and particularly religious texts, tapestries, tables and scrolls include gold leaf, which creates glare when trying to scan, distorting the captured image.

“And characteristics that you can’t get from even the most beautiful coffee table book – indentations in substrates, brush stroke techniques and chisel depth on a tablet or relief are important attributes that preservationists, archeologists, curators, appraisers, students and scientists want to know about.”

METIS addressed these challenges with its DRS Syncrolight system and its Scan Director software:

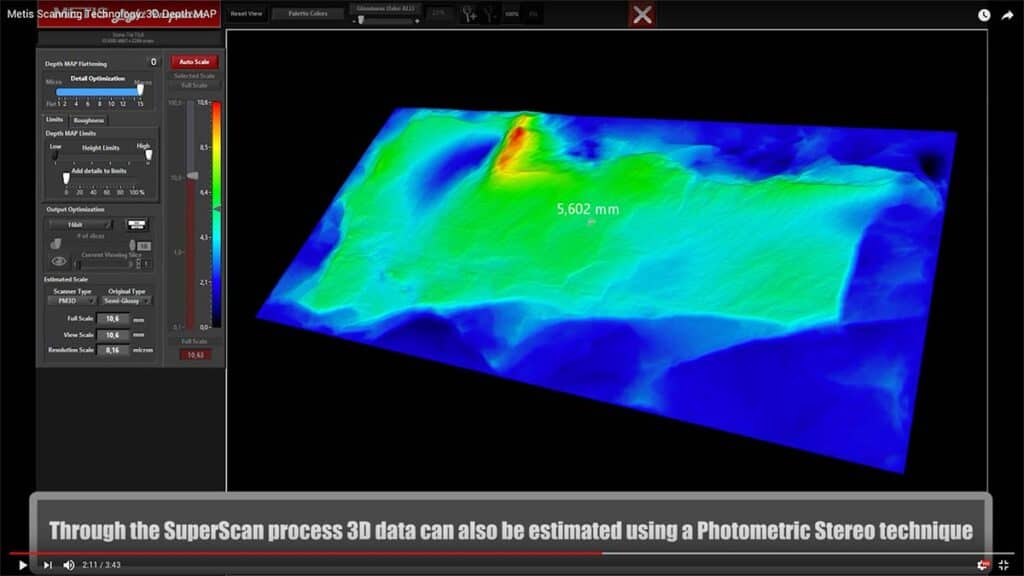

This video shows the unique ability of METIS scanners to extrapolate high resolution 3D data from the scanned originals surface based on the Photometric Stereo technique. 2D Color data and 3D data are perfectly in register. More at https://www.metis-group.com

The Syncrolight system uses a lightbar with four independently controlled light sources – two positioned at wide angles, left and right, for texture and contrast; and two at high angles, left and right, for gloss and refection information. The lightbar and camera makes four passes over the original, gathering unique data revealed by each of the light sources.

Once scanned, the company’s Scan Director software uses specially developed photography algorithms to do mathematically what is not possible (or not allowed!) to do physically to the specimens:

- Mathematically smooth out wrinkled, bowed and uneven surfaces while retaining a 1:1 ratio in the information.

- Optically gather light information from multiple angles, and then mathematically remove glossiness and glare without the use of polarizing or other data-reducing filters.

- Mathematically calculate surface texture and provide accurate surface depth measurements to capture brush stokes, chisel depths and even pen or pencil indentations.

“Our software is truly unique in the market because of the way you can control all of the lighting and surface information,” says Lawrence. “You can literally dial in the different light sources to get exactly the characteristics you want to see, change your viewing perspective, even to the point of entering negative values to reduce glare and glossiness.

“The only way you can cut glare with other scanner systems is to add a polarizing filter to the camera lens, which unfortunately filters out a lot of color information you need to create an accurate reproduction. With a Metis, this challenge can be overcome with a simple adjustment in the software without losing any data. In fact, the software is so powerful it’s almost like having the original still on the scanner bed for as long as you need to get your file just the way you want it.”

Preserving our planet’s natural heritage is as important as preserving our civilization’s cultural heritage.

METIS has been quite successful with museums and institutions and is now bringing what they’ve learned to the decorative surfacing world.

“You see it in the news every week…we’re losing some of our most beautiful wood species to deforesting and unregulated unethical harvesting and trade practices,” says Lawrence. “Rosewood is nearing commercial extinction, largely thanks to furniture producers in China, to the point that the world’s top acoustic guitar builders can’t even buy for their top-of-the-line instruments.

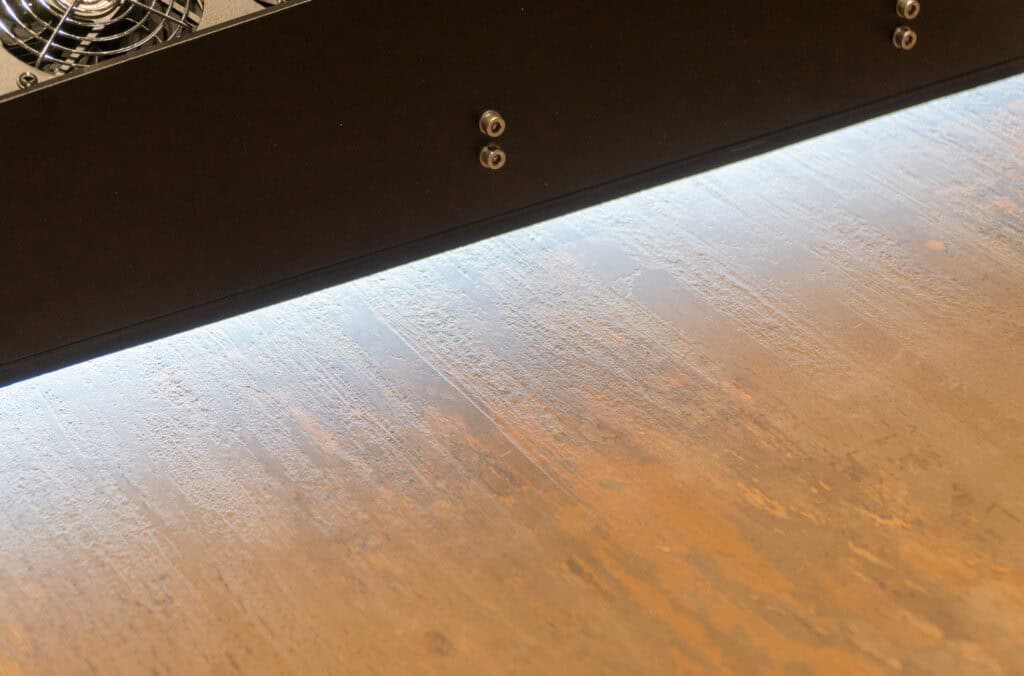

“Our scanning technology, along with the great digital and rotogravure printing suppliers out there, can create stunning reproductions of the finest and rarest woods, even species that have been extinct for decades. As long as we have a good ‘hero specimen,’ a piece we can capture, the rest of the world can use it in any application they can imagine, without guilt!

“As a frequent business traveler, I constantly see beautiful woods and veneers used in applications that are far too abusive for the durability they offer,” says Lawrence. Why would anyone ever put real walnut in an elevator cab, or to suffer careless abuse as a hotel’s combination TV stand/minifridge cabinet a hotel room? That’s the definition of waste. A much better option is to specify a more durable laminate material, printed from a high-definition scan of the real thing, and engineered to take that kind of punishment.”

The METIS scanner’s ability to capture texture adds another level of realism to today’s laminate materials, because producers are able to emboss woodgrains and other textures in perfect alignment with the printed design, says Lawrence.

“There are some materials out there that are so realistic even furniture industry veterans can’t tell it from real wood.”

— Rob Lawrence

Because of the amount of data captured, and the level of control in the Scan Director software, a single panel of scanned material can yield literally thousands of different output possibilities.

“Without getting too far into the mathematical weeds, the actual number of combinations is 100 to the eighth power,” says Lawrence. “The bottom line is, the level of creativity you can mine from a single scan of wood, stone, textile, or just about any other material, is unlimited.”

Increase your Material Intelligence:

Subscribe now!Learn about Metis’ role in developing new decors

METIS is the leader in the Industrial and Cultural Heritage markets and with the great success of its patents and the extraordinary Photometric Stereo 3D Application in the surface scanning, became the undisputed point of reference for a sight into the future of digitization.

METIS scanners are designed with the specific needs of the decor market. By combining innovative software with cutting-edge technologies, one device can provide a number of outputs, including 2D color scan, 3D data generation and glossiness data generation.

Established in 1985, CGS is a world leader in digital proofing, color management and production workflows for the professional graphic arts market. CGS represents METIS in North America.