PVC can be a more sustainable solution when paired properly

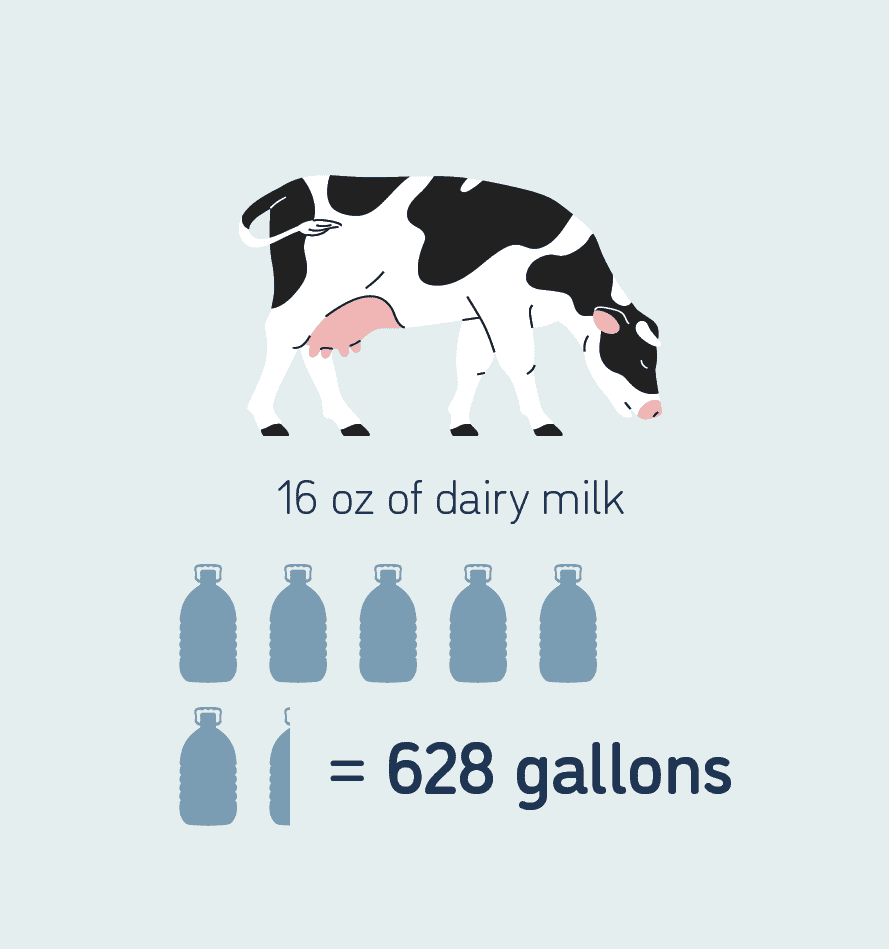

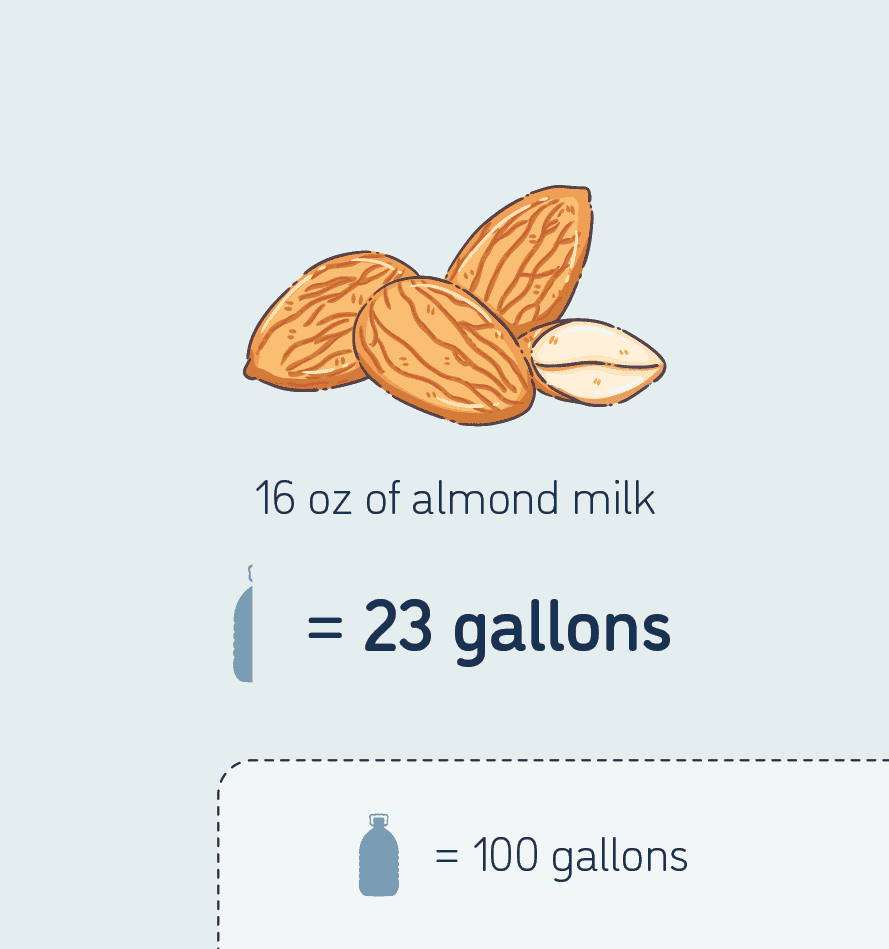

PVC (polyvinyl chloride) is like almond milk. It’s a popular alternative to its traditional counterpart, but critics can rightly claim that it still consumes a significant amount of resources to produce. But have you seen how much water a cow consumes for traditional milk? Compared to cow’s milk, almond milk is clearly a more sustainable solution.

How many gallons does it take to produce…

VERSUS

PVC obviously isn’t milk. But like almond milk, it can be a sustainable solution in the context of traditional alternatives.

PVC is the third most produced plastic in the world behind polyethylene plastic found in bottles, plastic bags, and some packages, and polypropylene, which is found in clothing, medical tools, cars, and even more packaging. PVC accounts for about 15% of global plastic production and is used in many applications like pipes, siding, flooring, wallcoverings, and more across hundreds of industries.

In its simplest form, PVC is made through three sub-processes: the production of chlorine, the production of vinyl chloride monomer (VCM), and the production of PVC itself.

It is true that:

- PVC is hard to recycle, and only a small percentage of it is ever reclaimed globally. In the US, PVC is barely recycled.

- When PVC is incinerated as waste, its chlorine-based composition can release harmful dioxins and hazardous byproducts.

- PVC has high lifecycle greenhouse gas emissions since producing PVC is energy-intensive.

But it is also true that PVC is self-extinguishing, meaning it can’t burn unless there is a constant flame or heat source.

It’s also true that PVC can be combined with other far more sustainable materials to extend its lifespan. Making products like siding or flooring last longer reduces overall consumption and ultimately reduces carbon emissions and resource consumption. We have to take a long view of a product or material (the earth indeed does over the next million years).

One Swedish study compared PVC flooring to traditional alternatives:

mPPE (PS)

Modified Poly(phenylene ether) with polystyrene

ELO

Epoxidized linseed oil

EMAA

Ethylene methacrylic acid

EVA

Ethylene vinyl acetate

They found a PVC vinyl floor had a Global Warming Potential (GWP) of ~417 g C02/m2 over its life. Compared to wood at 424g. PVC had the lowest environmental impact overall in their baseline scenario (.docx), particularly because it is optimized for production and often uses co-products efficiently, particularly when paired with renewable energy sources.

We remind people constantly that wood is the single best building material on the planet because of its highly sustainable and low-carbon nature — even accounting for the loss of a mature tree in the short term.

More on comparisons between a wood and PVC floor

A wood floor, for example, has a lifespan of approximately 10 years in a high-volume building, such as a hotel, hospital, or apartment complex. Linoleum can last up to 20 years.

But to maintain either the linoleum or wood floor (both are far more climate-friendly compared to PVC by itself) in that time span requires chemicals, oils, varnishes, and other additives that are routinely added to keep them clean, looking new, and serviceable.

A better solution is combining a small amount of PVC as a covering for that same wood or linoleum floor, which can double or triple its lifespan with a marginal amount more carbon offset and dramatically reduce maintenance costs, cleaning, and chemical use and reduce the amount of overall PVC used.

Likewise for wood siding for building exteriors. PVC siding (“vinyl siding” to most) is significantly cheaper per square foot, which is one reason it’s used so extensively in North America. Wood siding and fiber cement boards are renewable and have lower manufacturing emissions than PVC. But wood requires regular painting or sealing, is prone to rotting and warping, and its biggest benefit — that it’s biodegradable — is also its biggest challenge. Most people don’t like to think of their home or business as actively biodegrading.

Using less PVC is the key step to a sustainable floor or surface

Perhaps the biggest benefit of PVC is that you simply need less of it less often. One Finnish hospital tracked its flooring over a 24-year period and realized that vinyl flooring saved €1.6 million on cleaning, reduced water, chemical, and energy use, and freed up labor to focus on other, more productive tasks.

As one final example, a PVC coating on a standard wood cabinet or desk can significantly increase the product’s lifespan. A hotel cabinet may last a year or two with normal use. But coating it in a thin veneer of vinyl can improve its longevity to as much as ten to fifteen years.

The lifecycle has to include the carbon costs of the procurement, manufacturing, transportation, retailing, and installation of a single cabinet repeated once every couple of years versus once every fifteen years.

PVC, like almond milk, looks like it’s an energy-intensive resource consumer on paper. However, when compared to alternatives like traditional cows, and considering the true lifecycle and use case, it becomes a much more sustainable, affordable, and high-quality option that reduces long-term consumption and environmental impact.

Or put another way, PVC is not unlike solar power: it is resource-intensive to build and procure in the short term, but when done well and thoughtfully, it is a smart long-term investment for you and the planet.