Architects and designers should know how different wood cuts affect the aesthetic of their projects

There’s more than one way to saw wood. And there are a lot of ways to change its appearance depending on your needs for durability and costs. Architecture and design projects can dramatically alter their budgets by altering wood cut choices.

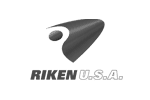

This is a simplified, cross-section of a tree, cut in half lengthwise along its center diameter:

You can imagine cutting this log in half again, in half vertically, or in a bunch of other ways. You can also see the various growth rings.

Hardwoods like oak and walnut can take as much as 80 years to mature for use in furniture, but can sometimes be harvested in half that depending on the growth cycles. Some fast-growing softwood species like poplar, pine, and Douglas fir can be planted and harvested in as little as 10–15 years, which is ideal for homebuilding and frames.

The growth rings matter to our woodcuts. To use every bit of the wood, we need to look at the grain. The grain tells us how and where to cut for various use cases, visible grain, aesthetics, and durability.

What are our options for using this tree to its fullest extent?

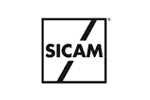

Plain sawn wood cuts (AKA, flat sawn) maximize efficiency with low labor

As the name suggests, this plain sawn cut is rather plain. Plain sawn is the most common cut method. It’s also the most economical since the process cuts parallel to the growth rings, resulting in flat boards. This cut results in a varied grain pattern instantly recognizable on tables, flooring, cabinetry, and other furniture like shelves and chairs. The grain features tall, distinctive peaks.

Plain sawn wood is efficient and produces the least waste. The result is that timber operations get more boards per log.

There are downsides. Plain sawn wood is prone to warping and cupping because the variable grain orientation runs in multiple directions. This “tugs” at all ends across the board and can cause uneven shrinkage when exposed to moisture and humidity.

Plain sawn wood is used most often for affordable furniture, building frames, and siding. You’ll find pine is most often plain sawn, since the “waves” look unique and it’s sustainable.

Wood is nature’s carbon storage

Don’t let the felling of trees for building projects make you think it’s inherently harmful to the environment. With proper management, wood is hands-down the best, most sustainable, most renewable resource we have. If you support building housing and care about the environment, you support using wood.

Read more about how wood is nature’s built-in carbon storage tool of choice »

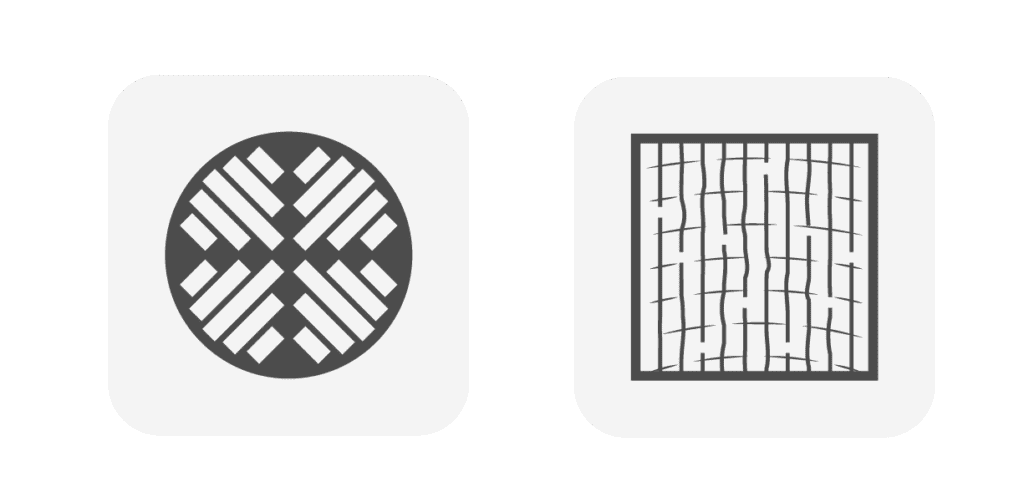

Quarter sawn wood cuts maximize durability of the wood

Quarter sawn is what it sounds like: a log cut into four quarters, then sliced at a 90-degree angle from the growth rings.

Quarter sawn boards have a more linear, “straight grain” pattern with distinct rays that resemble sonar waves or solar flares emanating across the board. They’re also less likely to warp or cup because the grain is more uniform with dimensional stability for architectural applications, like trim.

Quarter sawn wood is the best choice for high-quality, high-end furniture, flooring, and even wooden musical instruments. If you need moisture-resistant wood that can resist cracking and splitting, use quarter-sawn wood.

Oak, white oak, and cedar are commonly quarter sawn. Because the grains are nearly entirely vertical, quarter sawn cuts showcase the grains and are mighty stable for high-demand use cases. Take cedar, which is a great choice for decks or wide-plank flooring and siding since it naturally resists rotting and decay.

Rift sawn wood is a stunning aesthetic choice

If you quarter a log and cut the boards at a 45-degree angle from the growth rings instead of the 90-degree angle we used in quarter sawn cuts, you get rift sawn.

You might use rift sawn boards if you need durable cuts that can withstand some abuse, like doors, desks, and drawers. But because rift sawn wood yields less usable wood from each log, it’s more expensive and isn’t recommended for larger projects, like flooring or cabinets.

Why use rift sawn over quarter sawn if it yields less? Because quarter sawn shows more “specks and flecks” between the wood fibers. Rift sawn has a more minimalist look and achieves more linear grain that’s ideal for millwork.

Cherry, maple, and walnut are commonly rift sawn. These species are highly uniform, and make for beautiful furniture and architectural trim. They resist warping and look great.

Live sawn is a unique combination of rift, plain, and quarter sawn cuts

This video shows a log being live sawn in a mill.

Live sawn wood cuts straight through the log, almost like slivers. It also looks a lot like plain sawn cuts, but there are differences. Plain sawn wood is sliced straight across, rotating the board to maximize yield. Live sawn boards are just cuts straight through the log, end-to-end, without rotating the log to reduce waste. You get more balanced grains and cuts, with a more unique texture than plain sawn. Live sawn also benefits from being less labor-intensive.

As a result, this very common cut of wood yields a combination of plain sawn, quarter sawn, and rift sawn grains. Live sawn wastes very little of the tree.

Live sawn cuts show all the rings, knots, and grain variations, too. It’s the truest and most “honest” cut, showing every bit of the tree’s history and growth. This make it a great contender for wide plank floors, decks, rustic furniture, and that “shabby chic” aesthetic that is natural and authentic to reclaimed wood, even when the wood wasn’t all that “reclaimed.”

Live sawn is used for reclaimed wood, accent walls, and other decorative use cases. Walnut is among the most popular live sawn wood, but any species with varied grain patterns and “irregular character” benefits from live sawn wood.

End grain cuts make for unique grain patterns

The “checkerboard” pattern you see in wood cutting boards and countertops use an end grain cut. End grain cuts are durable, resistant to wear (like from knives, because knives penetrate between the fibers instead of across them, preserving sharpness), and make for unique patterns.

End grain cuts are sometimes used for flooring. But the grain is susceptible to moisture absorption, so proper sealing and maintenance is a concern. End grain cuts are not ideal for biologically sensitive areas like hospitals. Architects should use end grain cuts when compressive strength is a critical factor.

Wood cut summary for architects and designers

| Cut Type | Visual Appearance | Durability / Stability | Best Uses | Cost Efficiency |

| Plain Sawn (Flat Sawn) | Wavy, cathedral-like peaks; highly varied grain | Prone to warping and cupping due to mixed grain orientation | Flooring, framing, siding, affordable furniture, shelving | ★ ★★ ★★ (Most efficient, least waste) |

| Quarter Sawn | Straight grain with decorative ray flecks; consistent look | Very stable; resists cupping, splitting, and seasonal movement | High-end flooring, cabinetry, musical instruments, mission-style furniture | ★ ★★ ☆☆ (Moderate yield, moderate waste) |

| Rift Sawn | Linear, uniform grain with minimal flecks; elegant and modern | Extremely stable, strong; less prone to distortion than plain sawn | Architectural millwork, doors, desks, trim, modern furniture | ★ ★☆☆☆ (Low yield, higher waste and more costly) |

| Live Sawn | Mix of plain, quarter, and rift patterns; full character of the tree | Moderately stable; combines strengths of multiple cuts | Wide-plank flooring, rustic furniture, reclaimed-style projects, feature walls | ★ ★★ ★ ☆ (Efficient, minimal waste) |

| End Grain | Checkerboard pattern; unique, small-block appearance | Excellent compressive strength; absorbs impacts well but is vulnerable to moisture | Butcher blocks, countertops, specialty flooring | ★ ☆☆☆☆ (Labor-intensive; not ideal for large-scale building) |